Air filters are key components in various applications such as automobiles and HVAC systems, ensuring clean air by capturing pollutants, particles, and other contaminants. Air filter paper folding machine play a key role in the entire manufacturing process for air filter manufacturers. They can automatically fold air filter paper, improve production efficiency, and ensure consistent product quality. In this blog, we will introduce the different types of air filters that air filter paper folding machines can produce and how these machines can optimize manufacturing.

What types of air filters can air filter paper folding machine produce?

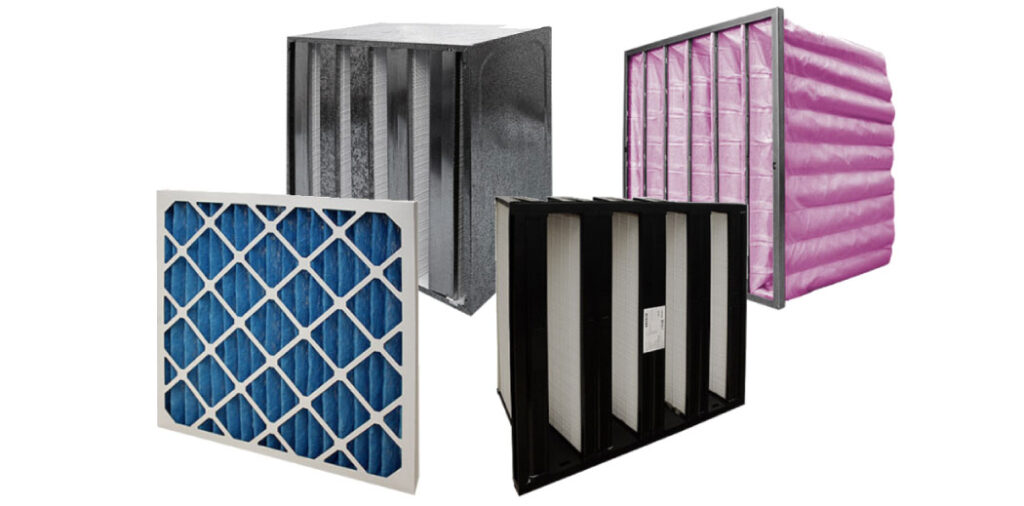

The most common types of air filters produced by air filter paper folding machines include pleated air filters, panel filters, and extended media filters. Pleated air filters are widely used in HVAC and industrial applications because their increased surface area maximizes filtration efficiency. Air filter paper folding machines can automate the pleating process, ensuring uniformity and consistency of each filter. Another type of filter that air filter paper folding machines can produce is a HEPA filter. Designed to capture tiny particles such as dust, pollen, mold, bacteria, and other harmful particles, these filters help to create high-performance HEPA filters by folding and pleating the air filter media.

How to Optimize Pleated Filter Production?

Air filter folding machines produce pleated air filters, among the most common filters. This type of filter is highly efficient due to its increased surface area, allowing it to capture more particles than non-pleated filters. Air filter folding machines play a key role in achieving the pleat pattern that gives these filters an increased surface area.

Air filter folding machines fold the filter media precisely and ensure the pleats are evenly spaced and highly consistent. This precision ensures that the pleated filter maintains better performance. The machine can also adjust the pleat depth and spacing to the specific requirements of different filter types, whether used in residential HVAC systems or automotive applications. Air filter folding machines also increase production speeds and reduce labor costs through automated processes.

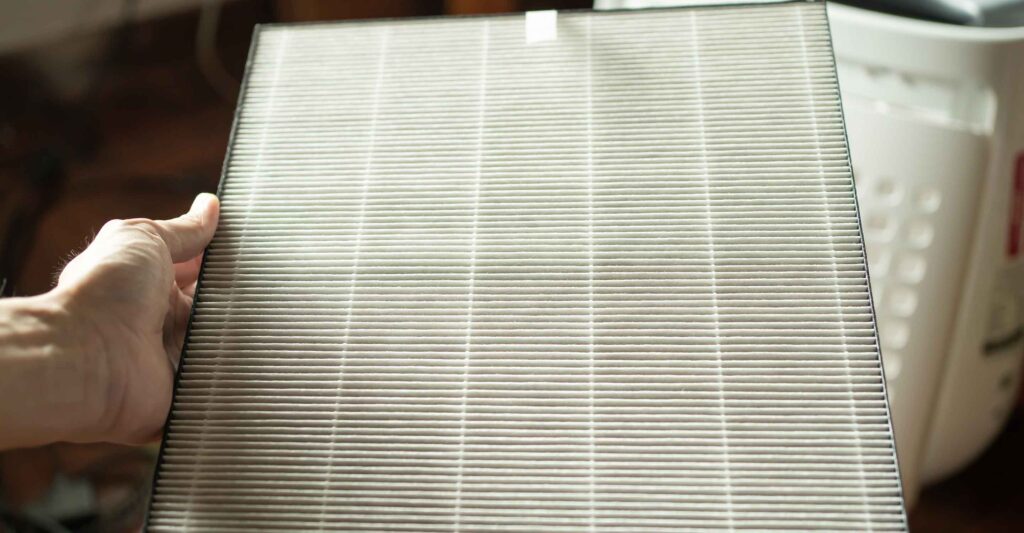

Producing HEPA filters using air filter folding machines

HEPA filters are critical in air purification systems, especially in sensitive environments such as hospitals, laboratories, and aerospace applications. At the same time, producing air filter folding machines is also the core of HEPA filters. Air filter paper folding machines also fold the media into precise pleats to increase the surface area, which is necessary to capture tiny particles. As with pleated filters, the machine evenly spaces and uniformly constructs each pleat. For feeding, they have a conveyor stock limiter to ensure the consistency of the pleated material and a magnetic powder brake on the feed shaft to ensure stable material tension during conveying. Air filter paper folding machines help manufacturers make HEPA filters used in high-end air purifiers, clean rooms, and even some vacuum cleaners.

Manufacturing Carbon and Activated Carbon Filters

Carbon filters, significantly activated carbon filters, are widely used for air purification in commercial and residential environments. These filters effectively remove odors, gases, and volatile organic compounds (VOCs) from the air, making them ideal for air conditioning, kitchens, and industrial ventilation systems.

Air filter paper folding machines can fold activated carbon-infused filter media to produce carbon filters. The machine folds the carbon-infused media correctly, resulting in a larger surface area for adsorption. This is particularly important because the more significant the surface area of the activated carbon, the more pollutants it can absorb. By automatically folding carbon-impregnated filter media, folding machines help manufacturers meet demand more efficiently and consistently.

Panel Filter Production

Panel filters are another type of air filter. People commonly use these filters in residential, commercial, and industrial HVAC systems. While they may not have the same pleat complexity as HEPA or carbon filters, Air filter paper folding machines can fold filter paper into specific pleat designs when producing panel filters to achieve the best balance between airflow and filtration efficiency. These filters can be made using standard filter media such as fiberglass or polyester. The advantage of using an air filter paper folding machine in panel filter production is that it can process large amounts of material quickly and efficiently. This makes it easier for manufacturers to meet market demands while maintaining product consistency.

Make filter production more flexible and diverse

Air filter paper folding machines can increase production efficiency, reduce costs, and ensure product quality. Whether it is producing pleated or HEPA filters, the versatility and automation these machines provide have changed the air filtration industry. The ability to deliver high-quality, high-efficiency filters when mass-producing, as well as air filter paper folding machines, can be an integral part of this process.