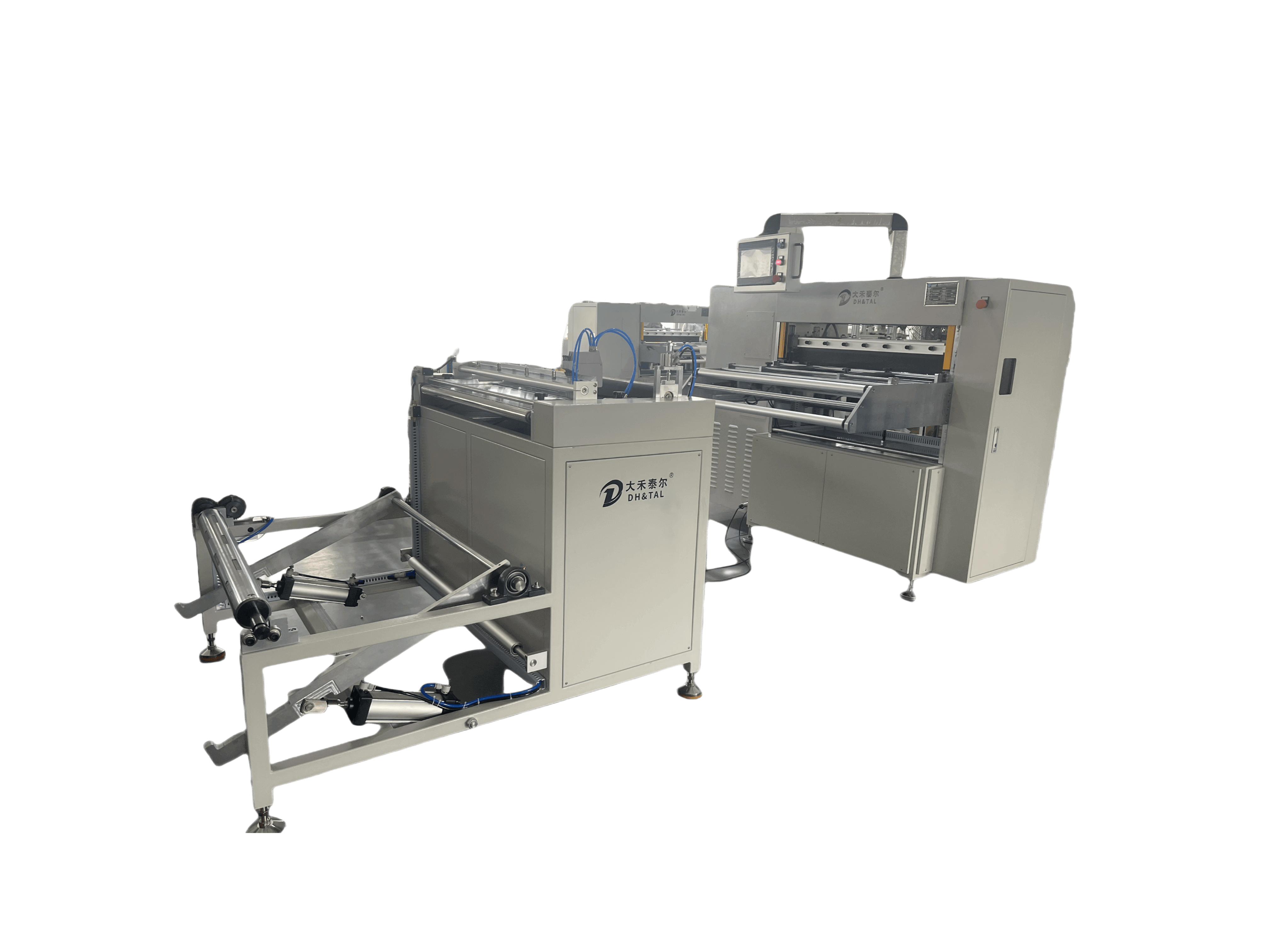

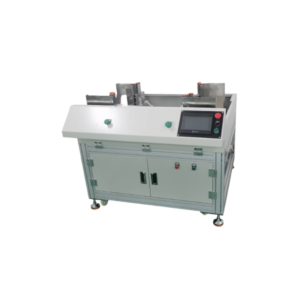

Paper pleating machine

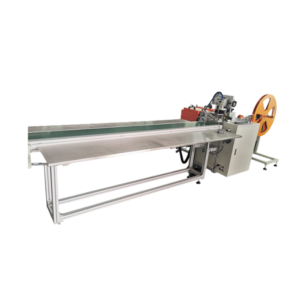

The paper pleating machine is a filter production equipment that integrates the functions of paper slitting and feeding and filter paper folding, with high efficiency and stable operation. The entire paper pleating machine adopts a steel structure, and the core components are equipped with magnetic powder brakes to ensure stable feeding tension and automatic shutdown function for lack of material. At the same time, the folding and lifting are driven by a servo motor to ensure stable forming, which is suitable for high-precision filter paper folding needs.

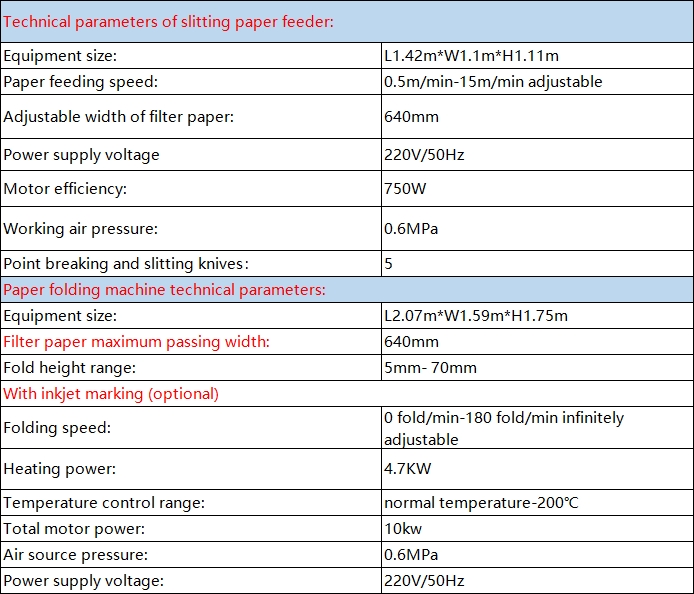

Equipment parameters:

Dahe Intelligence can provide customized services for paper pleating machines with non-standard specifications and sizes to better meet the production needs of different customers.

Equipment Advantages:

The paper folding machine includes a slitting and feeding machine and a filter paper folding machine. The feeding machine consists of a feeding mechanism and a traction mechanism. The feeding shaft of the feeding mechanism is a pneumatic shaft with a scale, and the feeding shaft is equipped with a magnetic powder brake to ensure the stability of the material tension during the conveying process. The indexing mechanism is driven by a 750W motor, and the feeding drive wheel has a cylinder lifting function for convenient feeding. The feeding has a conveying and storage limit function to ensure the consistency of the folded material. The equipment has an automatic shutdown function when there is no material.

- The whole machine is made of steel.

- The folding and lifting adopt a servo motor to drive the gear rack to lift, which is more stable.

- The front workbench has a preheating function, and the rear workbench has a heating and insulation function to ensure stable forming.

- A safety light is provided to avoid damage caused by operating errors.

- The workbench uses a stepper motor to drive the linear guide rail to move up and down, and different folding heights can be adjusted.

- The folding discharge section has a pressure strip to press the folded filter paper. The pressure strip can be increased or decreased according to actual conditions.

- The front and rear boxes of the equipment are equipped with observation windows to facilitate observation and parameter adjustment to reduce material waste.

- The equipment has an automatic shutdown alarm function for lack of material.

Equipment use:

Used to complete the filter paper pleating process in the air filter manufacturing industry.

Products suitable for manufacturing:

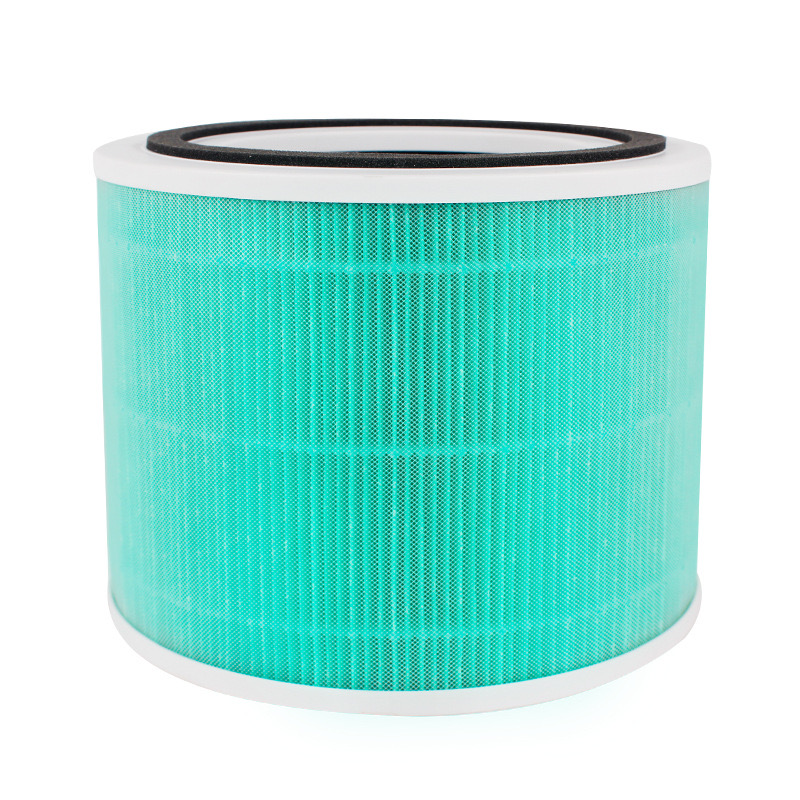

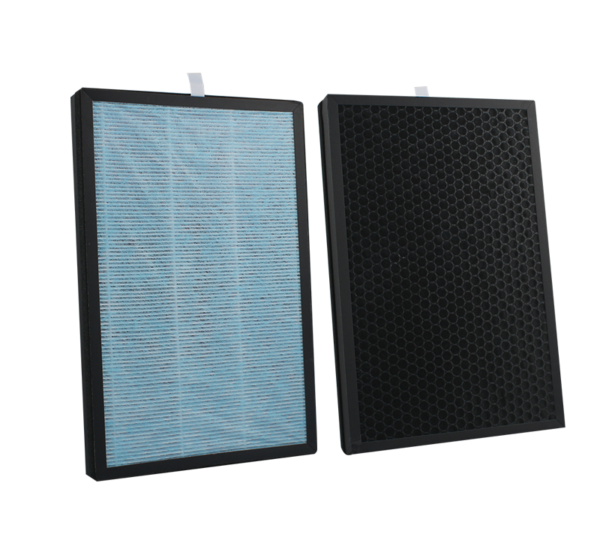

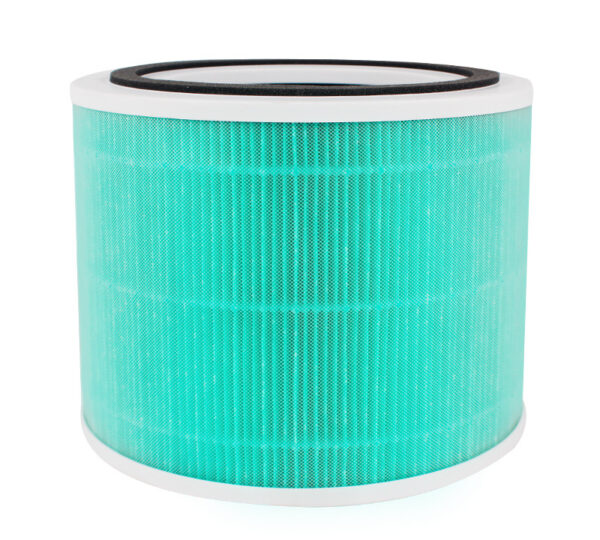

Round filters

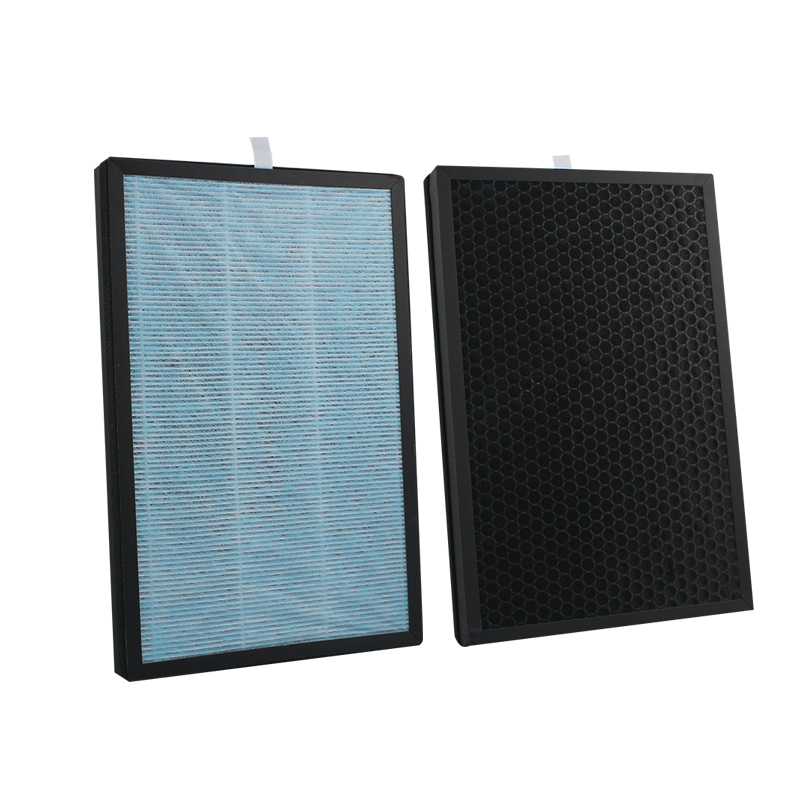

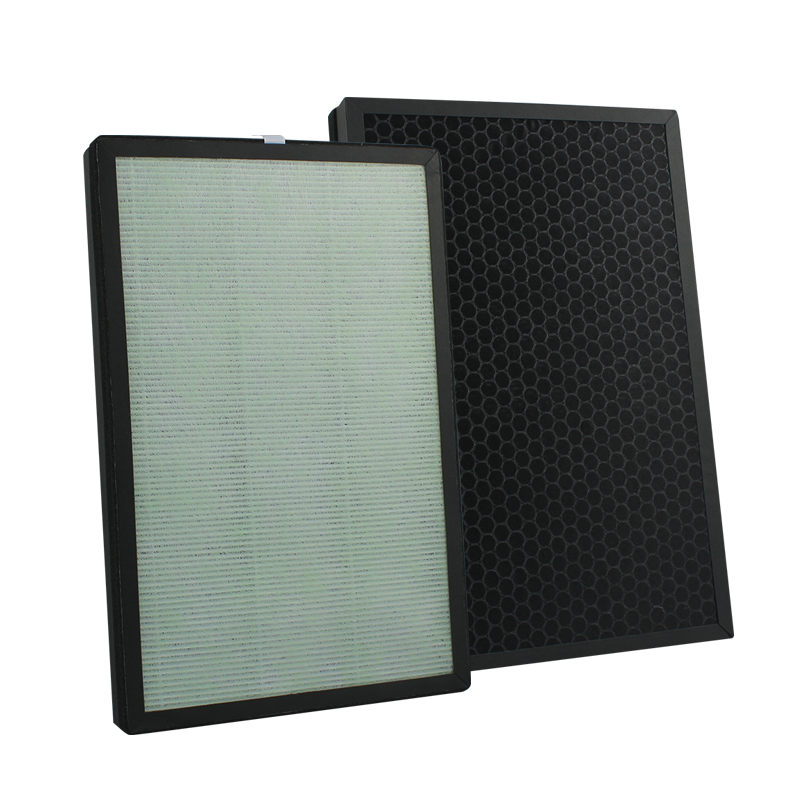

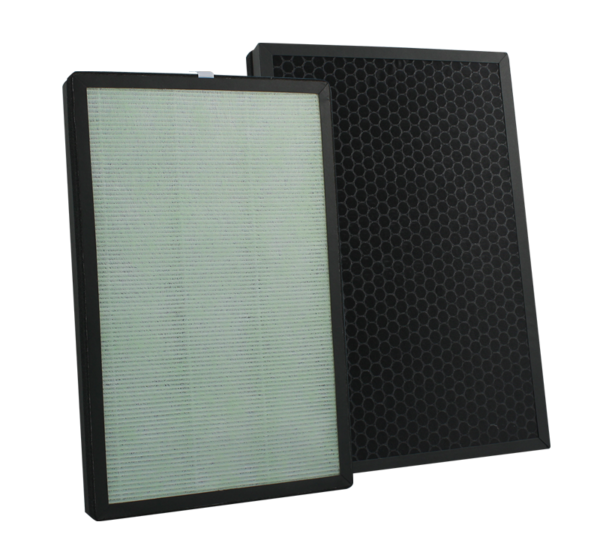

Square filters

Professional filter equipment manufacturer

Please leave your contact information and our professional business consultants will provide you with corresponding solutions and quotations and answer your questions.

Customer Reviews

“This pleating machine has revolutionized our production process. We can now meet high demand and produce 40% faster without sacrificing quality or efficiency.”

James Murray

“The Paper pleating machine has increased the precision and efficiency of our production process. Our filter performance has improved significantly, which is critical to our customers.”

David Green

Join Our Newsletter

Related Products

Related products

-

Household air purification filter

Automatic edge strip scraping machine-Single station

Rated 0 out of 5Read more -

Automobile air conditioning filter

Automatic edge trimming machine-4 corners

Rated 0 out of 5Read more

Contact

- Building 3, Simin Industrial Zone, No. 56 Xiaoxiang Wenming Road, Wanjiang District, Dongguan City

- +86 13560883391

- tableliu@126.com

- WhatsApp:+8613560883391

SHORTCUT LINKS

- Home

- Product

- About Us

- Video Case

- Contact Us

- Blog

PRODUCTS

- Automobile air conditioning filter production

- Household air purification filter

- Vacuum cleaner and sweeping robot filter

- Hot melt adhesive machine

- Precision machinery parts processing

Contact us

© Copyright 2024 Technical Support: Lezhan