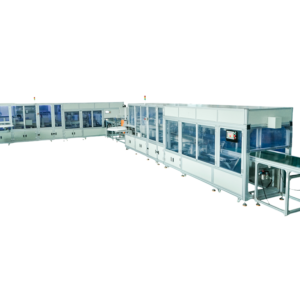

Fully automatic fiberglass origami glue injection production line

The fully automatic fiberglass origami glue injection production line integrates automatic feeding, precise folding, multi-function glue spraying and rapid curing. The equipment is equipped with a magnetic powder brake tension regulator, a 50-liter hot melt glue machine, and an independent glue spraying system supporting a variety of glue spraying modes. It is controlled by a touch screen, is easy to operate, and has high production efficiency. The folding and molding mechanism is adjustable and suitable for glass fiber filter elements of different specifications.

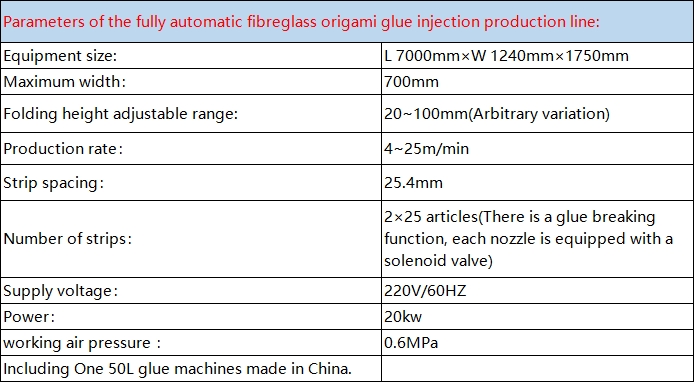

Equipment parameters:

Dahe Intelligence can provide customized services for fully automatic fiberglass origami glue injection production lines with non-standard specifications and sizes to better meet the production needs of different customers.

Equipment advantages:

- Automatic feeding function, no need to manually lift the material to the discharge position.

- The feeding shaft adopts an air expansion shaft, which is convenient for material replacement.

- The magnetic powder brake tension regulator controls the tension unwinding, ensuring the equipment runs more stably.

- When making products that are not folded high, you only need to enter the relevant parameters on the touch screen, and there is no need to replace the folding roller.

- After folding, the corresponding slitting knife can be selected to cut the filter paper according to the product requirements.

- The glueing system consists of a 50-litre hot melt machine and two sets of independent glue spraying systems and is equipped with a corresponding number of solenoid valves.

- One set of glue guns is connected to the cylinder for easy feeding, and the other set is connected to the bevel gear and screw. The distance between the filter paper and the glue gun can be adjusted by rotating the hand wheel, without adjusting on both sides.

- Glue gun glue spraying performance: connection glue spraying, single-sided and double-sided glue injection, fold glue injection, and offset glue injection.

- The origami wave-forming mechanism can simultaneously realize the up-and-down forward and backward movement adjustment through the hand wheel, which is suitable for filter elements of various specifications and different heights.

- Speed control: The folding and conveyor belt speeds can be controlled synchronously on the display screen, and the spacing between papers can be set.

- Fans are used to dissipate heat after injection and folding to solidify the glue line quickly.

- The belt mechanism is extended to prevent the glue line of the filter element from being completely solidified after forming.

Equipment use:

The Fully automatic fiberglass origami glue injection production line is mainly used for folding and producing glass fibre filters, with paper folding and glue injection completed in one process.

Customer site pictures:

Professional filter equipment manufacturer

Please leave your contact information and our professional business consultants will provide you with corresponding solutions and quotations and answer your questions.

Customer Reviews

“This pleating machine has revolutionized our production process. We can now meet high demand and produce 40% faster without sacrificing quality or efficiency.”

James Murray

“The Paper pleating machine has increased the precision and efficiency of our production process. Our filter performance has improved significantly, which is critical to our customers.”

David Green

Join Our Newsletter

Related Products

Related products

-

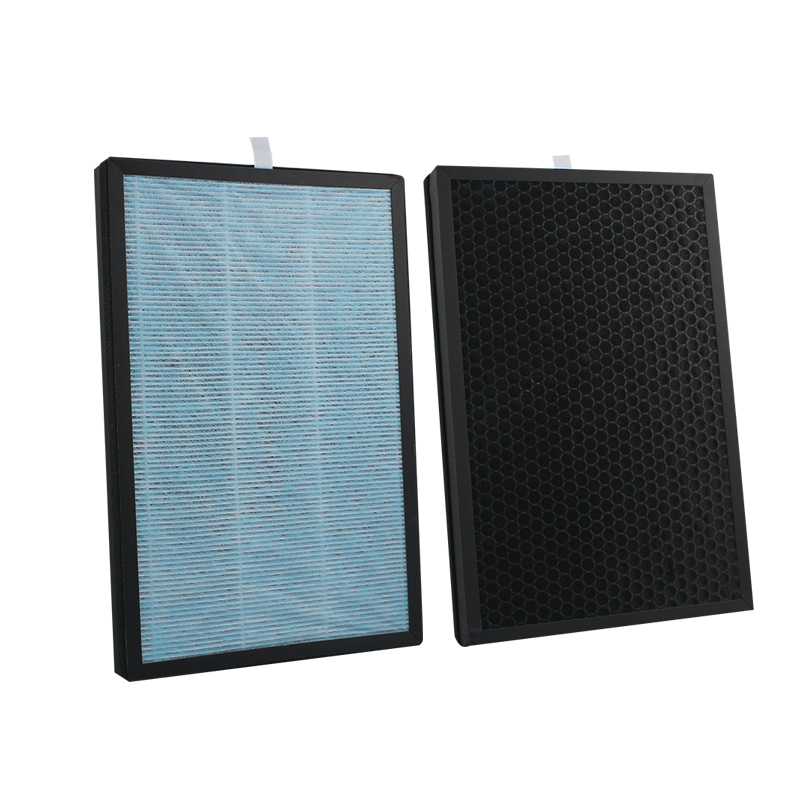

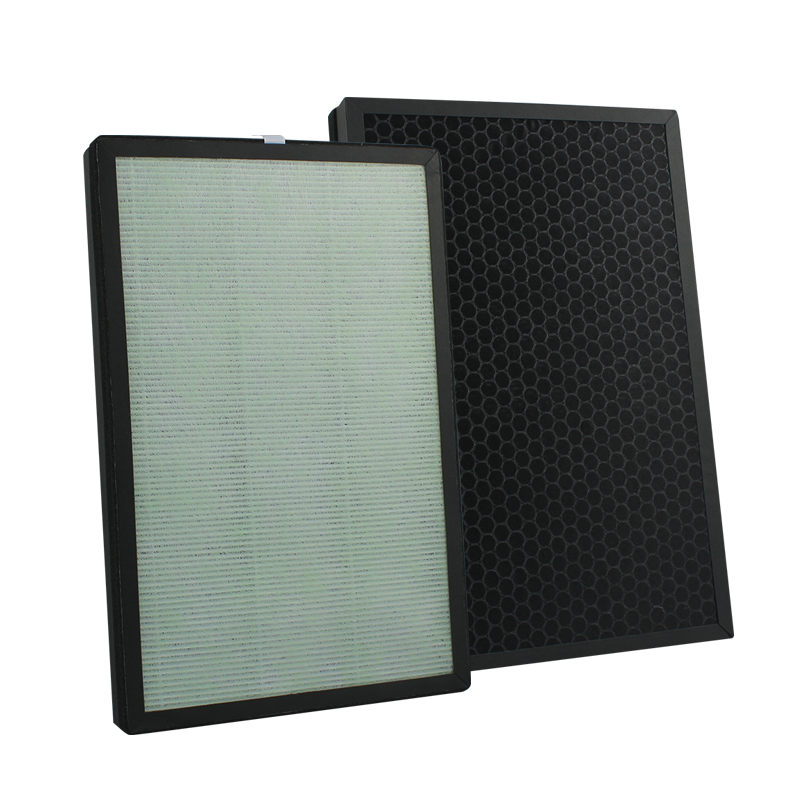

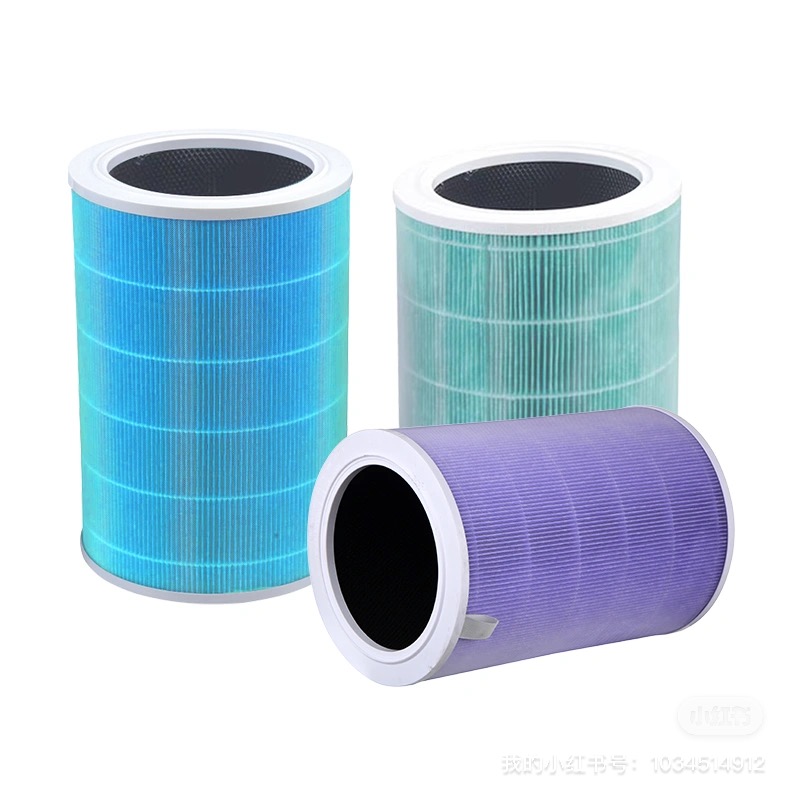

Household air purification filter

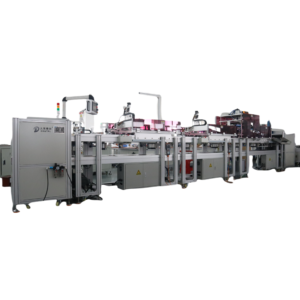

Fully automatic filter screen four welt production line

Rated 0 out of 5Read more -

Household air purification filter

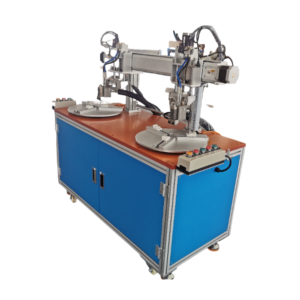

Circular dispensing machine-double station

Rated 0 out of 5Read more -

Automobile air conditioning filter

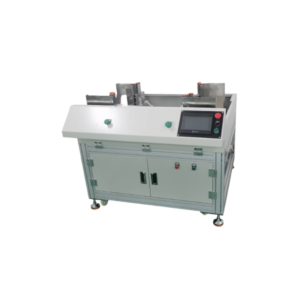

Automatic edge trimming machine-4 corners

Rated 0 out of 5Read more

Contact

- Building 3, Simin Industrial Zone, No. 56 Xiaoxiang Wenming Road, Wanjiang District, Dongguan City

- +86 13560883391

- tableliu@126.com

- WhatsApp:+8613560883391

SHORTCUT LINKS

- Home

- Product

- About Us

- Video Case

- Contact Us

- Blog

PRODUCTS

- Automobile air conditioning filter production

- Household air purification filter

- Vacuum cleaner and sweeping robot filter

- Hot melt adhesive machine

- Precision machinery parts processing

Contact us

© Copyright 2024 Technical Support: Lezhan