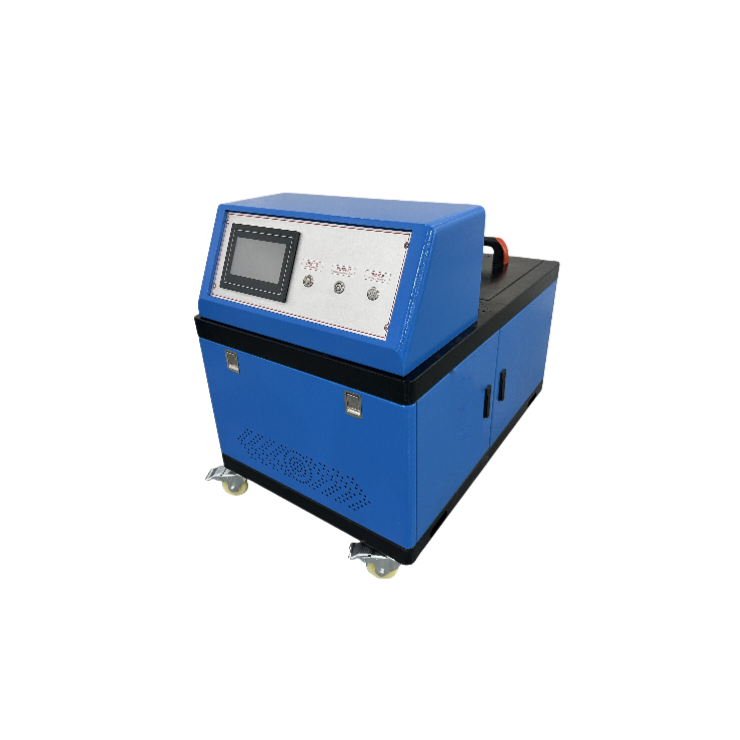

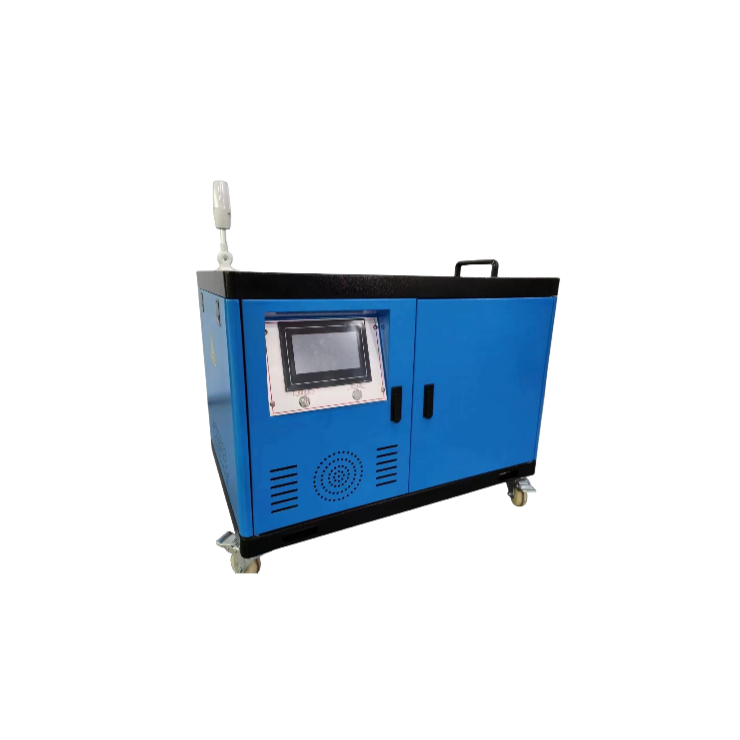

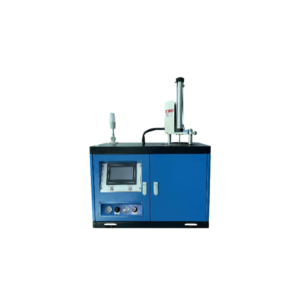

6020M Intelligent Hot Melt Adhesive Machine

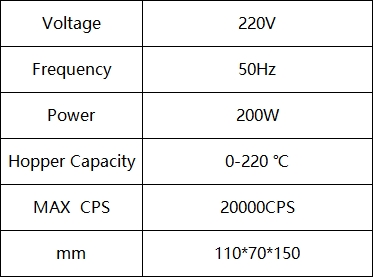

6020M host technical parameters:

Features and parameters:

- A new guide reflux device (safety valve) is needed to adjust pressure and flow more accurately and stably.

- Frame-type body structure, simple and quick installation and maintenance.

- The double-layer permeable Teflon anti-carbonization coating in the melting cylinder and the progressive fin-shaped heating bottom layer improve sol efficiency.

- Double-layer filtration of the body flow channel effectively prevents iron filings and debris from entering the glue channel and prevents the flow pump from getting stuck and damaged.

- Precision metering pump/piston pump ensures the stability and continuity of glue output.

- Intelligent PID constant temperature, timed automatic on/off preheating, one-button insulation, no glue alarm, and other abnormal alarms.

- Sol equipment, heating hose, and dispensing valve are not allowed to leak glue. The hose will not solidify if not used for a long time, and there is no more residue in the barrel.

- Imported heating wire and K-type universal thermocouple from the United States, quantitative glue output, encoder glue automatic glue spray compensation.

6020M host technical parameters:

Characteristics and parameters of hot melt adhesive insulation hose:

It uses a heating wire imported from the United States and a sensor imported from Germany to heat and control the temperature. It is resistant to high pressure and can be bent. It is used to connect the hot melt adhesive host and the spray gun group. The length can be customized according to actual needs. The interior is a heat-resistant and pressure-resistant American imported Teflon hose, and the exterior is covered with a stainless steel metal braided mesh to enhance its pressure resistance. The multi-layer insulation material and heat-resistant insulation material cover the heating wire to extend the service life and improve safety. It uses American aerospace technology plug-ins and Teflon liner, which is not easy to carbonize and has a long service life.

Automated production lines have a flexible installation method without space restrictions; they use Teflon high-pressure pipes and thickened liners (wall thickness 1.2MM). It effectively prevents the carbonization of hot melt adhesive, and the working pressure can reach 120KG.

HS hot melt adhesive manual glue gun characteristics and parameters:

The new generation of gun body shells in 2018 is made of imported materials, which can withstand 300 degrees high temperature, ensuring that it will not deform under long-term high-temperature use, and the gun group is light and convenient.

1. The unique protective gear design prevents operators from accidentally getting scalded during work.

2. Make up for the work demand that the fixed gun group cannot be moved.

3. The universal joint combines European advanced technology, which is flexible and durable.

4. The imported heating tube and imported temperature sensor from the United States have accurate temperature control.

300NE high-speed spray gun characteristics and parameters:

1. Adopting imported Teflon liners from the United States, high temperature and high pressure, good flexibility, and more effectively reduce carbonization.

2. By adopting military high-temperature insulation materials, silicone bellows are highly efficient in heat preservation, have low power consumption, are 50% power saving, and have good heat preservation performance.

3. Independently developed fast electrical connectors, safe and reliable, in line with European industrial electrical standards.

4. High-efficiency fibre heating wire material has excellent uniform heating performance and durability.

5. There are also a variety of domestic and foreign universal connectors, which can be used in various brands of glue machines.

300NE high-speed spray gun technical parameters:

Customer Reviews

“This pleating machine has revolutionized our production process. We can now meet high demand and produce 40% faster without sacrificing quality or efficiency.”

James Murray

“The Paper pleating machine has increased the precision and efficiency of our production process. Our filter performance has improved significantly, which is critical to our customers.”

David Green

Join Our Newsletter

Related Products

Related products

Contact

- Building 3, Simin Industrial Zone, No. 56 Xiaoxiang Wenming Road, Wanjiang District, Dongguan City

- +86 13560883391

- tableliu1984@gmail.com

- WhatsApp:+8613560883391

SHORTCUT LINKS

- Home

- Product

- About Us

- Video Case

- Contact Us

- Blog

PRODUCTS

- Automobile air conditioning filter production

- Household air purification filter

- Vacuum cleaner and sweeping robot filter

- Hot melt adhesive machine

- Precision machinery parts processing

Contact us

© Copyright 2024 Technical Support: Lezhan