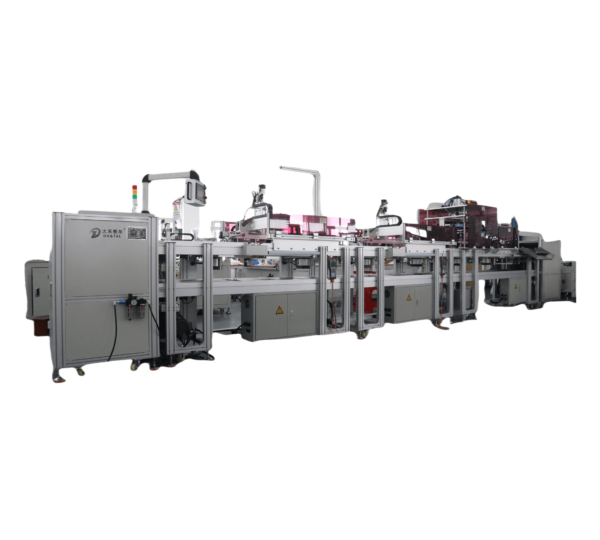

The filter side strip pasting machine is a key part of the air filter production. It is designed to paste continuous side strips along both sides of the air filter, enhancing the final product’s structural integrity and improving its overall durability. By automating the pasting process, manual labour can be reduced, errors can be minimized, and each filter can be guaranteed to meet strict quality standards. The importance of the filter side strip pasting machine lies in its core design of seamlessly pasting side strips, which play a role in reinforcing the air filter, preventing deformation and ensuring that the air filter maintains its shape stability during long-term use.

The role of the filter side strip pasting machine in air filter production

The filter side strip pasting machine is designed to enhance the structural integrity of air filters. By pasting side strips on both sides, the machine strengthens the filter frame, prevents deformation and ensures long-term durability. These side strips provide necessary reinforcement, significantly when air filters must withstand high airflow and pressure. Without a precise and efficient pasting process, air filters may suffer from inconsistent quality, leading to performance issues and potential failures in HVAC systems, automotive filtration and industrial air purification. Automation of the process ensures that each filter meets strict quality standards, thereby reducing defects and improving overall production efficiency.

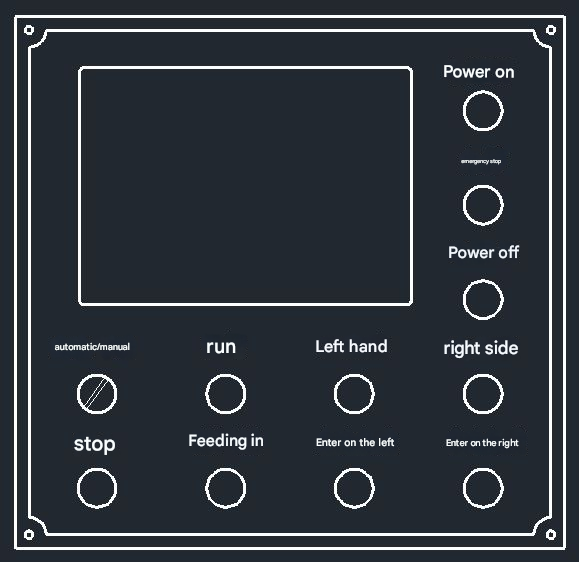

PLC Control and Touchscreen Operation

The filter side strip application machines incorporate PLC control and touchscreen operation. The PLC, as the machine’s control centre, can process inputs from a range of sensors, monitor the performance of the tensioning coil, and adjust the speed and positioning of the side strip material in real-time. This level of control is critical to ensuring that the side strip is applied evenly and consistently along the air filter.

The user-friendly touchscreen interface is another key aspect of the machine’s design. It allows the operator to interact with the system intuitively, set up production runs and modify parameters on the fly. It also facilitates quick troubleshooting when problems arise. The operator can easily adjust the width of the side strip, the pressure applied to the material, and the duration of the cooling process. One of the main benefits of using a PLC control system is achieving repeatability in production. Once engineers determine the optimal settings for a specific air filter design, the machine accurately reproduces these conditions each time it processes a new batch.

Automatic Sizing and Tensioning Coil Functionality

The filter side strip application machine’s automatic sizing mechanism differs from traditional manual adjustment systems. This innovative design enables the machine to detect the size of the air filter and automatically recalibrate the application process to accommodate those specifications. Switching between different filter sizes does not require time-consuming manual adjustments, significantly reducing downtime and improving overall production efficiency.

The tensioning coil plays an equally important role, working with the size adjustment mechanism to ensure that the side strip material is fed at a consistent and controlled rate. The tensioning coil automatically adjusts the tension based on feedback from sensors monitoring the process. This continuous adjustment prevents problems such as loose material or over-tightening, which can cause uneven bonding or even damage the side strip. Most importantly, the automatic adjustment and tensioning functions help reduce the possibility of human error, resulting in a more robust production process.

The blowing cooling mechanism integrated into the filter side strip pasting machine

An essential factor in ensuring the durability and reliability of the air filter is the fast and efficient cooling of the adhesive after pasting the side strip. The filter side strip pasting machine adopts an advanced blowing cooling mechanism, which plays a vital role in curing the adhesive and strengthening the bond between the side strip and the air filter. This integration not only improves the overall quality of the final product but also shortens the production cycle.

The blowing cooling mechanism coordinates perfectly with the pasting process. When the operator applies the side strip material to the air filter, the cooling system immediately activates, directing a controlled flow of cold air onto the newly applied material. This rapid cooling process quickly cures the adhesive, ensuring that the side strip is firmly and evenly adhered along the entire edge of the filter. This results in a more potent product that can withstand the rigours of long-term use without the risk of delamination or other failures.

Benefits and Production Improvements

Using a filter side strip applicator in air filter production offers a range of benefits, including quality, efficiency and cost-effectiveness. By automatically applying continuous side strips, manufacturers can achieve consistency that is difficult to replicate with manual methods. Uniformly applied side strips not only strengthen the structural integrity of the air filter but also improve its overall performance by preventing problems such as leaks or misalignment. With a consistent bond, air filters can better maintain shape and function even under challenging operating conditions. Regarding operational efficiency, the filter side strip applicator significantly reduces production downtime. Its automatic sizing and tensioning features eliminate the need for frequent manual recalibration, allowing production to continue uninterrupted even when switching between different product models.

Importance of Filter Side Strip Pasting Machines

The importance of filter side pasting machines in the production of air filters enables manufacturers to improve product quality and increase production efficiency and cost-effectiveness. Consistent application of side strips ensures that each air filter withstands the demands of extended use, while automated features reduce the potential for human error and minimize downtime during production changeovers. This results in a more stable, reliable supply chain, essential to meeting customer demands in today’s fast-paced market.