Filter manufacturing is a delicate and complex process that requires accuracy, consistency, and efficiency. Human errors in this process can lead to filter defects, material waste, and increased production costs. Many manufacturers are turning to automation and advanced equipment, such as paper pleating machines, to alleviate these issues. These machines are designed to streamline the pleating process, ensuring filters are produced with the highest quality and minimal errors. This guide will also share how paper pleating machines can help reduce human errors in filter manufacturing.

Improve Visibility with Observation Windows on Paper Pleating Machines

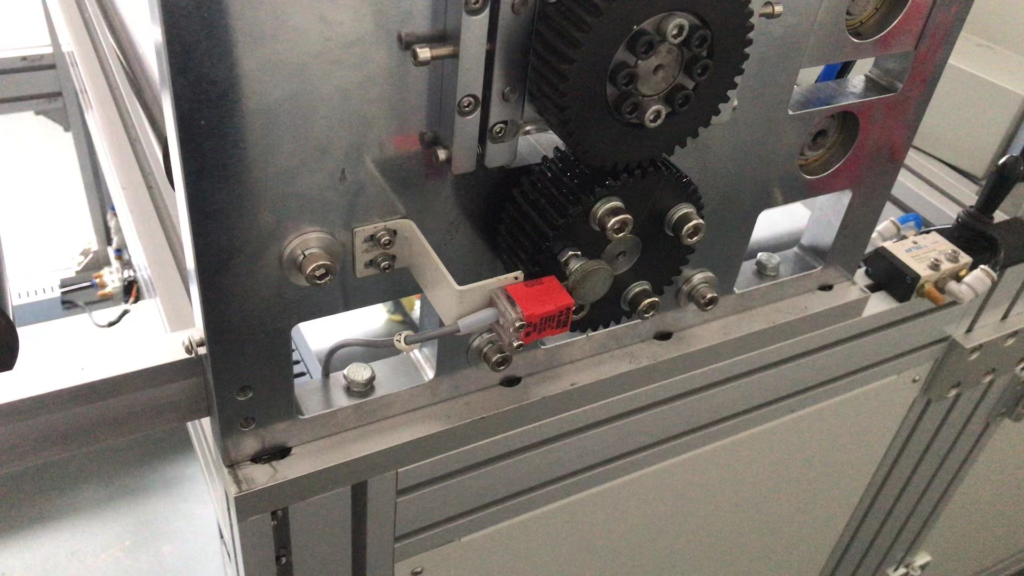

Human errors in filter manufacturing often stem from blind spots in manual processes. Dahe Intelligent’s paper pleating machines have dual observation windows on the front and back chambers to solve this problem, allowing operators to view pleat-formation and material flow in real-time. For example, during the production of HEPA filters, operators can monitor the alignment of paper layers without stopping the machine, reducing the need for disruptive manual inspections. If operators notice anomalies such as incorrect pleat formation, misalignment, or material blockage, they can take corrective actions immediately to prevent defects from affecting the entire production batch.

A German automotive filter manufacturer reported a 40% reduction in misaligned pleats after adopting Dahe Intelligent’s machines because operators can instantly adjust feed rate or tension settings while watching the process. This transparency minimizes the guesswork and ensures consistent output.

Automatically adjust parameters to eliminate manual errors.

Pleat parameters such as depth, speed, and pressure are prone to inconsistencies if manually calibrated during filter production. Dahe Intelligent’s paper pleating machines feature an automatic parameter adjustment feature that adjusts settings based on material type and environmental conditions. For example, when switching from synthetic filter media to a cellulose blend, the machine’s sensors detect the thickness change and recalibrate pleat pressure within seconds. A U.S. HVAC supplier used the system to reduce setup errors by 75% and achieve uniform pleat density across over 10,000 filters. The machine’s touchscreen interface also stores preset profiles for commonly used materials, allowing operators to load configurations with a single click – eliminating manual entry errors.

Prevent production interruptions with automatic stop alarms in paper pleating machines.

Failure to detect material jams or shortages in time can result in costly downtime and defective batches. Dahe’s paper pleating machines incorporate smart sensors that trigger automatic stops and alarms when an anomaly occurs. For example, if the paper roll is about to run out, the machine pauses and sounds an alarm, giving the operator time to reload without interrupting the pleating cycle. This automatic shutdown feature prevents the machine from running out of material, ensuring that the pleating process remains uninterrupted and that production quality is maintained.

It also reduces the risk of human error, as operators are often busy managing multiple tasks and may not notice material exhaustion in real-time. The alarm system alerts operators to problems before they affect the end product. In a case study of a filter producer in Vietnam, this feature reduced material waste by 30% and avoided 15 hours of downtime per month. In addition, the system logs error codes and suggests troubleshooting steps, allowing even novice operators to resolve issues quickly.

Real-time monitoring and adjustments

Another benefit of a paper pleating machine is that operators can adjust the pleating process in real-time. Manufacturers typically equip these machines with a user-friendly control panel and interface that allows operators to adjust parameters easily. Operators can modify settings such as pleat depth, spacing, and speed to meet the specific requirements of the filter being produced.

By offering these customizable settings, paper pleating machines give operators greater control over the process while reducing the potential for error. You must make these adjustments manually using traditional methods, which often result in inconsistencies. However, with an automated system, you can make precise adjustments quickly and accurately, ensuring that each filter meets the required standards. This flexibility is particularly useful in high-demand environments with critical turnaround times.

Long-term Benefits

The long-term benefits of incorporating paper pleating machines into filter manufacturing are clear. These machines provide a significant return on investment by reducing human error, increasing production efficiency, and reducing material waste. They help manufacturers maintain high-quality standards, which is critical in industries that rely on filters to produce products. Additionally, the automation provided by paper pleating machines reduces reliance on manual labor, allowing workers to focus on other tasks. This increases productivity and improves workplace safety, as operators no longer have to perform repetitive manual tasks that can lead to fatigue and errors. The long-term impact is a more streamlined, efficient, cost-effective manufacturing process.

Reduce human error

Dahe’s paper pleating machines are designed to address the root causes of human error in filter manufacturing: visibility gaps, manual adjustments, and reactive workflows. These machines deliver precision, consistency, and operational efficiency by combining viewing windows, automatic alerts, and self-optimizing systems.