A critical part of the filter assembly process is the side strip application, which involves attaching the side strips to the filter media. This task requires high accuracy, which can be achieved using a filter side strip pasting machine. However, errors can still occur during the side strip application process, even with the best filter production equipment. These errors can lead to problems such as inconsistent adhesive application, misalignment, and poor bonding, which can affect the performance and durability of the final product. Therefore, this guide shares some common mistakes when attaching side strips and provides corresponding solutions to explain how to avoid these problems.

The Importance of Accurate Side Strip Application in Filter Manufacturing

Side strips ensure the filter’s structural integrity and sealing effect. If the side strips are not applied correctly, various problems can occur, including leaks, reduced filtration efficiency, and shortened filter life. The process of the filter side strip pasting machine involves using a strip of material (usually rubber or foam) to the side of the filter media. This process is very good at forming a tight seal between the filter media and the housing. If the side strips are not applied correctly, it will result in an incomplete seal, allowing contaminants to bypass the filter and reduce efficiency.

Common Errors in Filter Side Strip Pasting Machine Production

Errors can also occur during the side strip pasting process of the filter side strip pasting machine, and various factors, such as machine settings, material inconsistencies, or operator errors, can cause these errors. One of the most common errors is inconsistent adhesive coverage. This can cause the adhesive to be too thick or too thin in some areas, resulting in poor bonding between the side strip and the filter media. We can solve this problem by regularly calibrating the adhesive dispensing system and maintaining the correct viscosity and flow rate.

Another common problem is side strip misalignment, which can occur if the operator does not correctly calibrate the alignment settings of the filter side strip pasting machine. Misalignment can cause uneven application and affect the quality of the final product. Regularly check its alignment settings and perform routine maintenance to ensure proper calibration. When the pressure setting is incorrect, the pressure is too low, and the adhesive may not bond properly. The side strip may deform or squeeze out if the pressure is too high. So, you need to optimize the pressure setting for the specific filter and material used.

Preventing errors in this area through automation technology

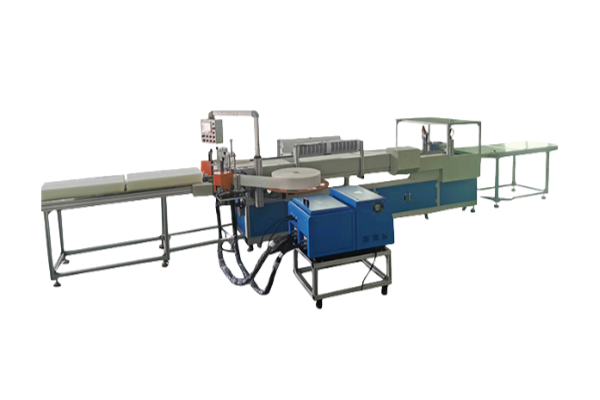

Dahe Intelligent provides the filter side strip pasting machine, which consists of a filter element preparation conveyor belt, left and right side strip feeding trays, glue melter, and other systems. The human-machine touch screen allows accurate positioning with pulse servo control to improve product and production quality. The automation brought by the entire production process helps to reduce the risk of errors in the side strip pasting process. It will better ensure the consistent application of adhesive, precise alignment of side strips, and optimal pressure levels. These automated systems can help simplify the production process, reduce human errors, and improve production efficiency.

In addition, the visual system integration can automatically detect misalignment or defects in the side strip application. These systems use cameras and sensors to monitor the application process in real-time and adjust as needed. At the same time, they also have a self-calibration system that can automatically adapt to different filter sizes or materials, further reducing the risk of errors.

Correctly calibrate the filter side strip pasting machine

Calibration is an essential aspect of preventing side strip application errors. You must properly calibrate and install the filter side strip pasting machine to ensure correct adhesive distribution, uniform side strip application, and consistent pressure. Dahe Intelligence will provide an equipment installation guide that you need to follow. Dahe Intelligence’s recommendations for calibration intervals and procedures. This includes checking the adhesive dispenser, adjusting the pressure setting, and verifying the alignment of the side strip applicator. Calibration tools such as laser alignment devices and pressure gauges can help ensure accurate settings.

At the same time, it is also important to calibrate the machine for different filter sizes and side strip materials. The characteristics of the filter media and side strips may vary, so you need to adjust the machine settings to reduce the possibility of errors and improve the overall quality of the production process.

For routine maintenance of the equipment

Over time, the components of the equipment, such as adhesive dispensers, pressure systems, and applicators, may wear, affecting their performance and accuracy. Regular maintenance helps identify and resolve potential problems before they cause errors or downtime. As a filter equipment manufacturer, we recommend developing a comprehensive maintenance plan that includes cleaning, lubrication, calibration, and parts replacement. Regularly check the machine for signs of wear, including damage to the adhesive dispenser, misalignment or pressure problems, and whether the software or control system is updated. Regular inspection and maintenance ensure smooth and efficient operation, reducing the possibility of errors.

Ensure error-free side strip production

Automation technology for filter side strip pasting machines, regular calibration, proper maintenance, consistent material quality, and other factors are essential in preventing errors and optimizing production processes. By implementing these practices, you can produce high-quality filters with greater consistency, reliability, and performance.