In industries ranging from home air conditioning systems to automotive air conditioning systems, filters are an essential part of ensuring the quality of these systems is safe and efficient. Therefore, filter manufacturing companies need specialized equipment to produce high-standard, high-quality filters. Dahe Intelligent can independently develop and provide the filter equipment needed to effectively and efficiently produce filters as a filter production equipment manufacturer. This guide will tell you how we support customized filter production equipment and provide various equipment types.

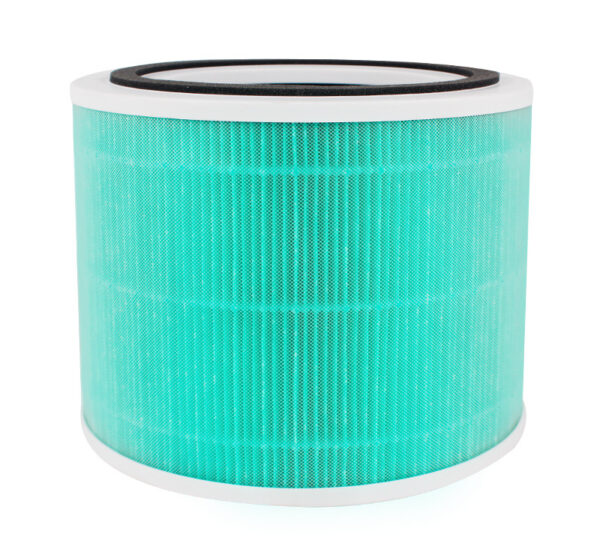

Filter production equipment manufacturers provide customized solutions for different industries

Dahe Intelligent provides equipment and customized solutions as a filter production equipment manufacturer. From air filtration to automotive air conditioning filtration, producing filters for these applications requires filter equipment with high production accuracy, robust reliability, and adaptability. For example, the automotive industry’s filter production equipment must meet strict air intake, oil filtration, and fuel filtration performance standards. Customized filter production equipment specializing in producing automotive air conditioning filters can create filters with specific characteristics that meet high flow, high-temperature resistance, and refined filtration capabilities. You need higher dirt retention capacity and longer service life if you produce home air conditioning filters. The equipment required for these filters must also accommodate larger filter sizes and different materials, such as activated carbon and other specialized media. Dahe Intelligence can customize and produce exclusive equipment based on the unique needs of each industry.

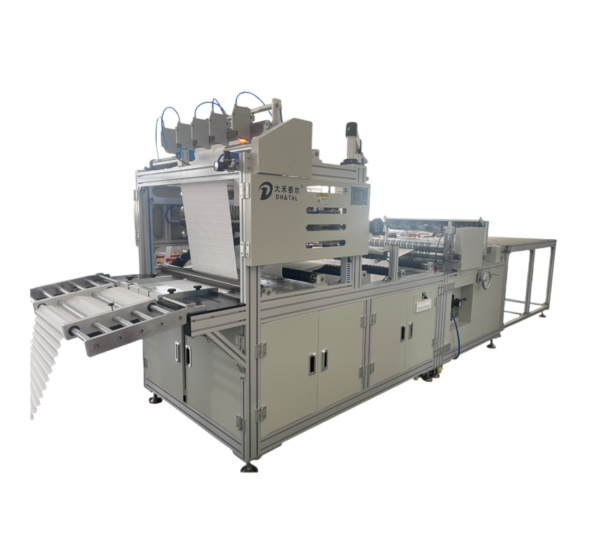

Filter production equipment is advanced and highly automated.

The critical factor that allows us to stand out as a filter production equipment manufacturer is our ability to integrate advanced technology and automation into manufacturing. The filter production equipment provided by Dahe Intelligence includes functions such as automatic winding, pleating, cutting, and sealing, which were once manual or semi-automated. Automation not only speeds up the production process but also reduces human errors, ensuring that the production of filters meets the highest quality standards. In addition, the automated system enables manufacturers to expand production without sacrificing quality or efficiency. At the same time, it is also equipped with a real-time monitoring system to track the performance of each unit on the production line. This data can be used to detect potential problems as early as possible so that timely adjustments can be made and downtime can be minimized.

Quality control of filter manufacturing

Unlike other filter production equipment manufacturers, the equipment we provide also ensures that manufacturers can produce filters with consistent quality and performance. In filter manufacturing, small changes in the production process can also lead to problems such as reduced filtration efficiency, leakage, or premature failure. This is a problem that many traditional filter production equipment are prone to. To solve these problems, we equip our filter production machines with advanced quality control systems to monitor all aspects of the production process. We integrate sensors into the equipment to measure the filter media’s thickness, density, and uniformity. If the production parameters are out of acceptable range, the equipment will automatically adjust or stop the process to prevent the production of defective filters.

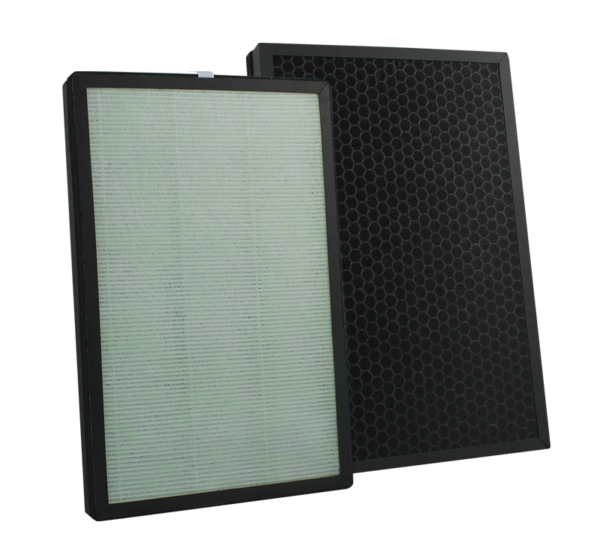

Material handling and flexibility

Filters can be made of various materials, including paper, fiberglass, carbon, polyester, and more. Each material has its own set of characteristics, such as thickness, flexibility, and porosity, which affect the filter’s performance. For manufacturers who produce filters for various purposes, the ability to efficiently handle different materials is essential. Dahe Intelligent designs production equipment with adjustable settings to allow operators to use other materials without significantly changing the production line. For example, some of these filter production equipment have interchangeable winding or pleating modules that can accommodate different types of filter media, providing greater versatility to the production process. At the same time, the material handling system ensures that the material is fed into the machine smoothly and without interruption, which can minimize downtime and improve the overall efficiency of the production process.

Filter production equipment manufacturers bring energy efficiency and cost benefits.

As the demand for more sustainable and cost-effective manufacturing solutions grows, energy efficiency has become an essential consideration for filter production equipment manufacturers. A filter production equipment manufacturer that prioritizes energy efficiency can help its customers reduce operating costs and meet environmental standards. The filter production equipment provided by Dahe Intelligent all adopts energy-saving features such as variable frequency drives (VFDs), optimized heating systems, and low-energy motors. These innovations reduce energy consumption during production, significantly saving costs in the long run. In addition to energy saving, these machines generally have a lower environmental impact, which is increasingly important for manufacturers who want to demonstrate sustainability.

Give you a more competitive advantage in the market

Filter production equipment manufacturers are essential partners for filter manufacturing companies. From customized solutions for different applications to advances in automation, energy efficiency, and material handling, Dahe Intelligent can provide professional equipment solutions.