Choosing the right equipment can optimize production lines and improve overall work efficiency. Selecting the proper filter production equipment manufacturer is critical to long-term success for the filter production industry, from air and water purification to automotive applications. The appropriate filter production equipment manufacturers can provide customized solutions that meet your specific production needs, helping you achieve higher productivity, lower costs and better product quality.

As a filter production equipment manufacturer, Dahe Intelligent provides various non-standard filter production solutions and can provide a variety of filter production lines, including fully automatic four-side hemming production lines, paper pleating machines and other filter production equipment. This article will explore the benefits of choosing the proper filter production equipment manufacturer and how Dahe Intelligent can help you optimize your production line for maximum efficiency.

Why is it important to choose the proper filter production equipment manufacturer?

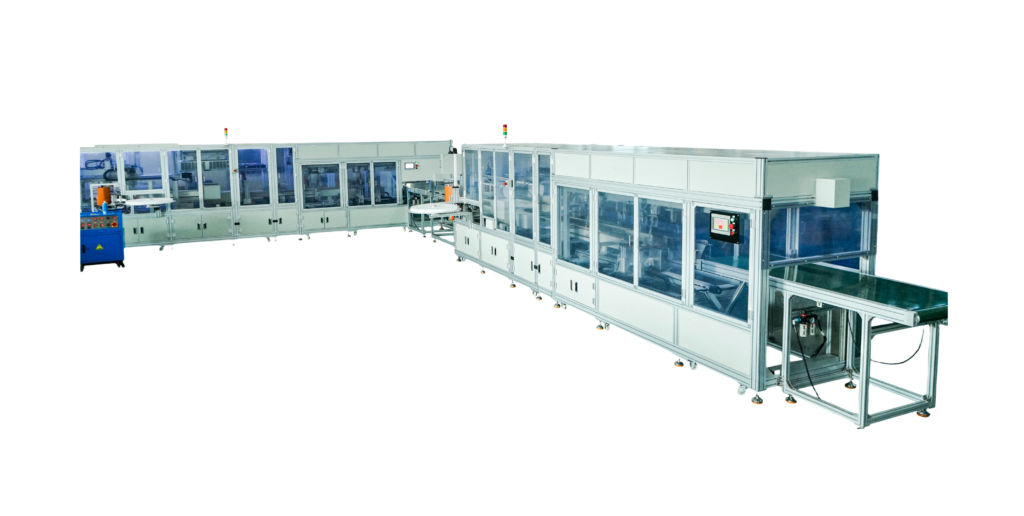

Choosing the right filter production equipment manufacturer is critical to ensuring the efficiency and quality of the production process. Good equipment manufacturers provide machinery and become partners in optimizing the entire production workflow. They will understand your unique needs, provide customized solutions, and provide technical support to ensure seamless integration with your existing systems. Dahe Intelligence is a filter production equipment manufacturer with independent R&D capabilities that can provide customized solutions to meet specific production needs. Our non-standard filter production capabilities enable us to design equipment that integrates seamlessly into any production line, ensuring that filter manufacturers can increase productivity and maintain high-quality standards. Therefore, by providing this non-standard customization service, you can get equipment that fits your workflow, thereby reducing downtime caused by modifying general-purpose machines.

Non-standard filter production solutions to meet unique needs

In many industries, standard filter production equipment may not be able to meet the unique specifications required for certain filter types. Whether the filters you produce have unusual sizes, materials or designs, you need a filter production equipment manufacturer that can provide non-standard customized solutions. Dahe Intelligent manufactures non-standard filter equipment based on your specific production needs.

From custom filter sizes to specialized mechanical configurations, Dahe Intelligent can design and manufacture equipment that meets your needs. This customization ensures that your production line runs smoothly and efficiently without compromising the quality or performance of the filter. For example, Dahe’s non-standard solutions include adjustable mould configurations, adaptive feeding systems, and precision cutting tools for handling delicate or unconventional materials. These systems are ideal for manufacturers of high-performance automobile filters, home air conditioners, and more.

Filter production equipment manufacturer with fully automated production lines

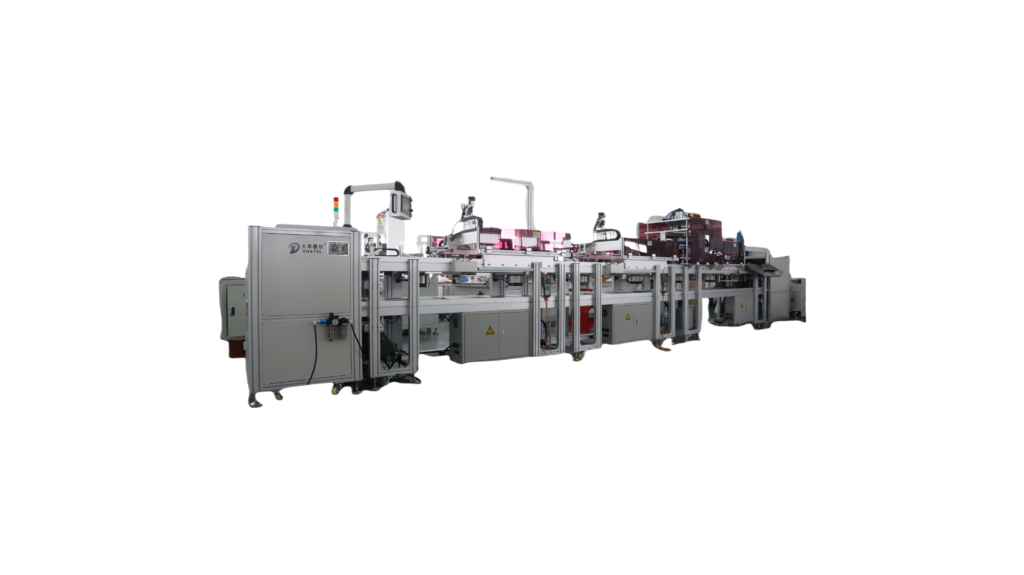

One of the significant advantages of working with an experienced filter production equipment manufacturer like Dahe Intelligent is the use of fully automated production lines. Automation is a key driver of efficiency, helping manufacturers reduce labor costs, minimize human errors, and speed up production time. At the same time, Dahe Intelligent can provide special filter equipment, such as fully automatic four-side crimping lines, Paper pleating machines, glass fibre origami glue injection lines, etc., to simplify filter production.

Automated systems ensure that production lines run continuously with minimal supervision, increasing production and maintaining consistent product quality. Equipped with advanced sensors and controls that monitor every step of the production process, these systems can detect defects such as uneven adhesive distribution or edge misalignment in real-time and make real-time adjustments to maintain optimal conditions. With automation, manufacturers can achieve higher production while retaining the precision and quality of filter manufacturing.

Bringing higher precision and speed to filter production equipment manufacturers

Advanced technology in filter production equipment is essential to maintaining consistent product quality. Dahe Intelligent uses state-of-the-art technology in its equipment, including advanced sensors and automated quality monitoring systems. These innovations ensure that the filters produced meet the highest standards of precision and performance. In terms of pleating machines, Dahe Intelligent’s pleating machines use servo drive control and an adaptive tension system to ensure uniform pleat depth and spacing even at high speeds. In addition, these machines support a variety of media, including cellulose, glass fiber, and nanofiber composites, and are suitable for various industries from air conditioning to automotive filtration.

At the same time, Dahe’s modular design allows for quick adjustment of custom pleat counts or angles, enabling manufacturers to switch between product lines without expensive downtime. By choosing a filter production equipment manufacturer that integrates the latest technology, companies can achieve excellent reliability, reduce defects, and improve the overall quality of their filter products.

Ensure Quality Assurance and Compliance

Regulatory compliance is a significant concern in filter manufacturing, especially for home filtration and automotive industries, where product failure can have serious consequences. Reputable filter production equipment manufacturers must ensure their machines meet international standards (e.g., ISO, ASTM) and promote compliance at every production stage.

Dahe Intelligent’s equipment is built with traceability in mind. Each machine generates a detailed production log, including time, material batch, and quality control results, simplifying audits and recalls. Their systems also incorporate failsafe features, such as automatic shutoffs in the event of parameter deviations, to prevent non-compliant products from entering the market. Choosing a manufacturer with strong quality protocols can safeguard your brand reputation and avoid costly penalties.

Elevate your production line together

Choosing the right filter production equipment manufacturer will affect your operations, from product quality and compliance to scalability and profitability. Dahe Intelligence can not only provide non-standard solutions, but also provide the most advanced automation and innovative technologies to provide future-oriented protection for your production line. Whether considering precision, flexibility and innovation, Dahe Intelligence enables manufacturers to meet changing market demands while maintaining strict quality standards.